WHAT CAN YOU GET FROM OUR BEST PRODUCT SOLUTIONS?

What do we need to consider when we develop a new product?-

Product positioning & functionFirst, identify your target population and the key features of your product.

Product positioning & functionFirst, identify your target population and the key features of your product. -

Cost budgetingYour business budget will help you determine your product design, process, and other production costs.

Cost budgetingYour business budget will help you determine your product design, process, and other production costs. -

Delivery timeAccording to your planned product launch time, we will reasonably arrange product design and production to ensure the final delivery on time.

Delivery timeAccording to your planned product launch time, we will reasonably arrange product design and production to ensure the final delivery on time.

_1687222691481.png)

-

Beauty device qualityBefore collaboration, it is important to consider whether the quality of the beauty device aligns with your brand. High-quality beauty devices can enhance consumer brand loyalty.

-

Beauty device selectionBefore starting product design, you need to consider aspects such as functionality, technology, materials, and processes. We will provide you with various options in these four aspects.

OPTIONS FOR BEAUTY DEVICE, MULTIPLE PLANS FOR YOUR CHOICE

-

According to efficacy

According to efficacy- Whitening

- Rejuvenation

- Wrinkle removal

- Lifting and Tightening

- Face-lift

- Cleansing

- Hair loss

- Repair

- Spot-fading

- Moisturizing

- Anti-acne

-

According to technology

According to technology- Radio-frequency technology

- EMS microcurrent technology

- LED technology

- Laser technology

- Photorejuvenation

- Ultrasonic lead-in

- Ultrasonic cleansing technology

- Low-temperature plasma technology

- High-frequency microcrystalline water needle penetration technology

- Import and export positive and negative ions

- Refrigeration and heating technology

- Vibration technology

-

According to material

According to material- Plastic: ABS, PC, PP, etc

- Food grade silicone

- Hardware

- Natural jade

- Titanium alloy

- Platinum

- Graphene

- Brushing

-

According to craft

According to craft- Vacuum plating, optical film coating

- Electroplate

- Since UV coating

- Rubber feel paint

- Hardware oxidation, stoving varnish

- Plastic, Metal drawing

- Decal, hydro graphics transfer printing

- IML, IMD in-mold decoration

- Double-color

ODM PROCESS

FITTOP strives to create a simple, safe, and efficient one-stop product development process.

1. Customer demand

According to the customer's demand information and customer's planned launch time of new products, reasonable arrangement of product design, development and production schedule, to ensure delivery on time.

2. Market research

Conduct research and analysis according to customers' needs and brand characteristics, as well as the target population of the product.

3. Product definition

Design competitive and unique product function definitions based on customer needs and market research.

4. Risk evaluation

Before and during product development, conduct DFMEA reliability design analysis on products, and conduct PFMEA process potential failure mode analysis during product realization to improve product quality and ensure product safety and reliability.

7. Prototype confirmation

After receiving the prototype, the customer experiences and tests the various parameters of the prototype according to the product definition and requirements. Confirm whether the prototype needs to be adjusted.

6. Prototyping

After the customer confirms the product ID design, according to the product definition, conduct electronic design and structural design, and estimate the prototype cost, product cost, and mold cost. After the customer confirms the cost of the prototype, the production of the prototype is started, and the prototype is expected to be submitted to the customer for confirmation within 3 weeks. After the prototype is completed, all functions and parameters are strictly checked.

5. Product design

According to the product definition confirmed by the customer, carry out product ID design (2-3 different product ID design schemes), after the customer confirms the product ID design, carry out electronic design and structural design. The customer's cost budget for new products is related to product function design and production process.

8. Mold design and production

After the customer confirms the prototype, provide the accurate product price and mold cost. After the customer's confirmation, the mold design and mold making will start. Mold making is expected to take 45 days + 15 days for mold fine-tuning.

9. Engineering Prototype

After the first mold trial, an engineering prototype will be provided to the customer for testing and confirmation. At the same time, the customer needs to provide packaging design documents. If necessary, we can provide a packaging design plan for the customer to confirm and make samples.

10. Small batch trial production

After the engineering prototype is confirmed, small-batch trial production will begin. After the trial production, the enterprise standard of the product will be formulated to prepare for formal mass production.

11. Mass production

After the small batch trial production is qualified and confirmed by the customer, mass production will start according to the customer's order.

WHAT YOU'LL GET BY PARTNERING WITH FITTOP

| FITTOP | Design Company | General Manufacturers | |

|---|---|---|---|

| Design cost | 5W( 0 cost after cooperation ) | 100W-200W+ | No design ability |

| Confidentiality degree | 1. Sign confidentiality agreement with customers 2. Strictly abide confidentiality agreement and never show it to a third party |

1. Possible to show cooperation cases to other parties 2. Weak awareness of confidentiality and risk of leakage |

Possible to produce and sell similar products to customers in the same industry |

| Design solution | 3. Rich experience in design and production, taking charge of the whole process from idea to production 4. All-round analysis is perfectly combined to provide three different sets of different design solutions |

No production ability and experience | No design ability |

| Quality Control | 1. Strong manufacturing supply chain 2. Strictly implement ISO9001 and ISO13485 quality management system 3. Complete quality testing lab |

No | General |

CONFIDENTIALITY AGREEMENT

In case of cooperation, we will sign a confidentiality agreement to maintain the safety of your products.

Customer drafting agreement

Both parties communicate and confirm the agreement

Sign and seal

Binding and storage of cooperation agreement

HIGH STANDARD PRODUCTION MANAGEMENT SYSTEM

ISO 9001:2015

Strictly execute ISO9001 since 2009

SERVICE AND AFTER-SALES SUPPORT

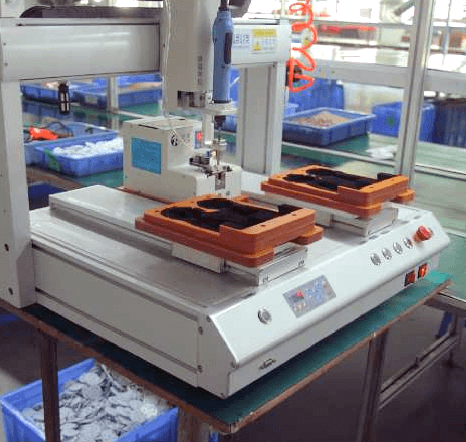

Modernized production equipment

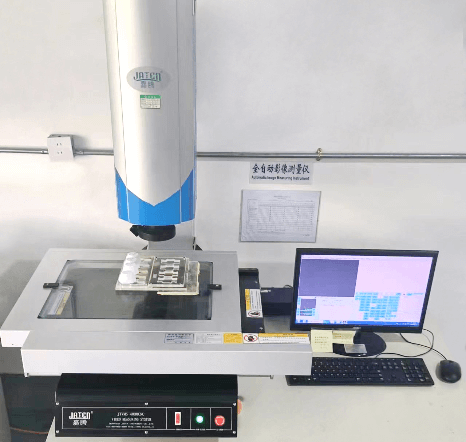

Advanced and well-equipped inspection laboratory

Full-process implementation of digital management

Feedback mechanism at key stages to timely monitor project progress

Completion of the entire process from product development to mass production in 3 to 4 months

Product's quality guarantee: 18 months

CUSTOMER WITNESS

We have satisfied customers from over 30 countries

We are sure it will be a great success.

Thanks again for your hard work and kindness. We look forward to the future.

We are still gathering all of our feedback from our team and will get back to you tomorrow, if possible. I will add notes to the Test Report that you provided.

We also need to receive more samples of brush head options and color options, We don't need the full device sample but just different samples of colors/brush heads.